What is Carbon Fiber?

Carbon fiber is a fascinating material that has revolutionized many industries. Composed primarily of carbon, it has unique properties that make it a material of choice for many applications. But what exactly is carbon fiber?

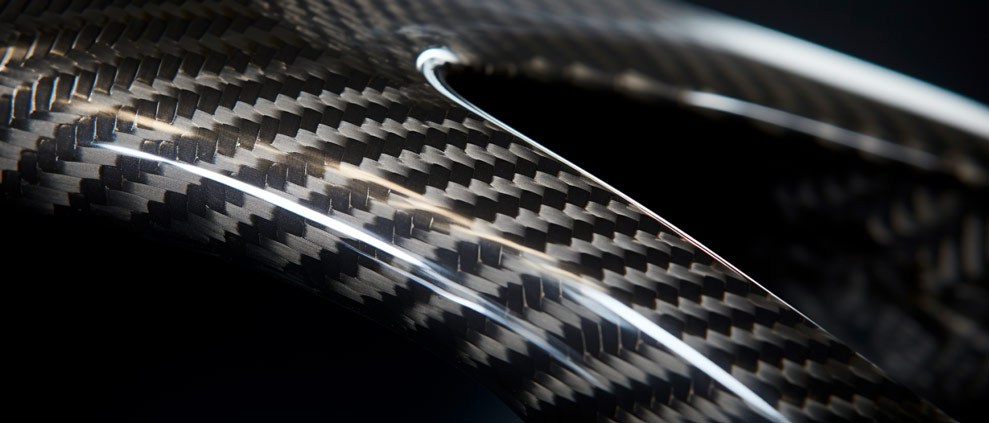

Carbon fiber is a composite material made up of thin carbon fibers. These fibers are extremely lightweight and strong, making them an ideal material for many applications. But what makes carbon fiber truly special is its crystal-like structure. This structure gives carbon fiber exceptional strength and high thermal conductivity.

But where does carbon fiber come from? Its history dates back to the 1950s, when researchers began studying the properties of carbon. Over the decades, many advancements have been made in the production and use of carbon fiber. Today, it is widely used in industries such as automotive, aerospace, and electronics.

The Chemical Composition of Carbon Fiber

Carbon fiber is primarily composed of carbon, but it can also contain other elements such as nitrogen, oxygen, and hydrogen. The precise chemical composition of carbon fiber can vary depending on the production process and the specifications required for a given application.

However, a high carbon content is essential for the unique properties of carbon fiber. In general, high-quality carbon fiber contains over 90% carbon.

The Specificities of Carbon Fiber

Carbon fiber has several specific properties that make it highly valued material. First, its strength is exceptional. It is five times stronger than steel, while being much lighter. Additionally, it is very rigid, making it ideal for applications requiring great stability.

In addition, carbon fiber is also highly thermally conductive. This means it can quickly dissipate heat, which is crucial in many applications, such as electronic components.

Finally, carbon fiber is also highly resistant to corrosion. Unlike steel and aluminum, it does not rust or corrode easily, making it an ideal material for aggressive environments.

With all these unique properties, it is not surprising that carbon fiber is widely used in many industries. In the next chapter, we will take a closer look at how carbon fiber is produced.

The Unique Properties of Carbon Fiber

Carbon fiber is an extraordinary material with unique properties that make it a preferred choice in many industries. Its strength, lightness, thermal conductivity, and corrosion resistance make it an exceptional material.

Remarkable Strength

Carbon fiber is extremely strong, much more so than steel for example. It offers exceptional mechanical strength, making it an ideal material for applications requiring great strength. Imagine a rope woven with thousands of carbon fibers, each fiber contributing to reinforcing the overall structure. It is this combination of strength and lightness that makes it a material of choice in the aerospace industry, notably for the manufacture of aircraft and satellites.

Unmatched Lightness

Carbon fiber is incredibly lightweight. In fact, it is up to five times lighter than steel while being equally strong. Imagine a material that allows you to significantly reduce the weight of an object without compromising its strength. This opens up infinite possibilities in many fields, from automotive to sporting equipment. For example, carbon fiber race cars can achieve incredible speeds thanks to their lightness, while providing optimal safety thanks to their strength.

Exceptional Thermal Conductivity

Carbon fiber is also renowned for its exceptional thermal conductivity. This means it is capable of dissipating heat more efficiently than many other materials. Imagine a thermal blanket that prevents heat from building up, thus avoiding any deformation or damage caused by high temperature. This is why carbon fiber is widely used in the electronics equipment industry, where thermal dissipation is crucial to ensure the proper functioning of electronic components.

Corrosion Resistance

Another major advantage of carbon fiber is its resistance to corrosion. Unlike steel, which can corrode over time, carbon fiber remains intact and does not oxidize. Imagine a structure that does not rust, even when exposed to extreme conditions. This makes it a perfect material for applications in corrosive environments, such as ships or coastal structures.

In conclusion, carbon fiber has unique properties that make it an exceptional material. Its strength, lightness, thermal conductivity, and corrosion resistance make it a preferred choice in many industrial fields. Whether in automotive, aerospace, electronics, or other sectors, carbon fiber offers unparalleled advantages compared to other materials. It paves the way for technological and aesthetic innovations, providing new possibilities for artisans and innovators worldwide.

How is Carbon Fiber Produced?

The production of carbon fiber is a complex and fascinating process. It is a true blend of art and science that gives rise to this incredibly strong and lightweight material. In this section, we will uncover the key steps in the production of carbon fiber, from precursor selection to carbonization.

Precursor Selection

It all begins with the selection of the precursor, which is the base material used to produce carbon fiber. There are different types of precursors, such as rayon, polyacrylonitrile (PAN), and coal tar pitch. Each precursor has its own characteristics and properties, allowing for carbon fibers with specific performance.

PAN is the most commonly used precursor due to its ability to produce high-quality carbon fibers. It is composed of polymer chains that are stretched and aligned during the production process, giving carbon fiber its exceptional strength and rigidity.

Oxidation and Carbonization

Once the precursor is chosen, it undergoes several treatments to transform into carbon fiber. The first of these treatments is oxidation. During this stage, the precursor is heated to high temperatures in a controlled environment, resulting in the release of volatile compounds and the formation of chemical bonds that stabilize the fiber’s structure.

After oxidation, the precursor undergoes carbonization. This involves heating the material to very high temperatures, often exceeding 1000 degrees Celsius, in an oxygen-free environment. This step eliminates all elements other than carbon, resulting in pure carbon fiber.

Carbonization is a delicate process that must be precisely controlled to achieve high-quality carbon fibers. Temperature, pressure, and heating duration parameters must be meticulously adjusted to ensure the formation of strong and regular carbon-carbon bonds.

Once carbonization is complete, the obtained carbon fibers are ready to be used in a variety of applications. They can be woven to form carbon fabrics, used as reinforcement in composites, or molded to create specific parts.

In conclusion, the production of carbon fiber is a complex process that requires technical expertise and meticulous attention to detail. Each step, from precursor selection to carbonization, is essential to obtain high-quality carbon fibers. Through this process, carbon fiber offers unique properties that make it a material of choice in many industries.

Various Uses of Carbon Fiber

Carbon fiber is a versatile material that finds numerous applications in various industries. Its unique combination of strength, lightweight, and thermal conductivity make it an ideal choice for many purposes. Here are some of the most common applications of carbon fiber:

1. Automotive Industry

Carbon fiber is widely used in the automotive industry to lighten vehicles and enhance their performance. It is used in manufacturing parts such as hoods, fenders, suspension elements, and chassis structures. Its high strength-to-weight ratio allows for reduced fuel consumption and improved energy efficiency of vehicles.

2. Aerospace and Aviation

Carbon fiber is also extensively used in the aerospace and aviation industry. It is employed in the construction of aircraft wings, fuselages, helicopter blades, and structural components. Its lightweight and strength contribute to a reduction in aircraft weight, resulting in better energy efficiency and increased payload capacity.

3. Sports and Recreation

Carbon fiber is highly appreciated in the sports and recreation industry due to its lightweight and strength. It is used in the manufacturing of bicycles, tennis rackets, fishing rods, golf clubs, and other sports equipment. It offers a significant improvement in performance, allowing athletes to push their limits.

4. Electronics

Carbon fiber is also utilized in the electronics industry. It is used to manufacture casings for electronic devices such as mobile phones, laptops, and tablets. Its strength and lightweight provide additional protection while reducing the overall weight of the devices.

5. Construction

Carbon fiber is increasingly used in the construction industry to reinforce structures and enhance their strength. It is used in the production of beams, columns, and structural cables. Its exceptional strength allows for a reduction in material quantity, resulting in cost savings and more sustainable construction.

In summary, carbon fiber is an extremely versatile material that finds numerous uses in various industries. Its combination of strength, lightweight, and thermal conductivity makes it an ideal choice for many applications, from the automotive industry to construction, aerospace, and sports. Its usage continues to expand and diversify, paving the way for new opportunities in innovation and progress.

The advantages of carbon fiber compared to other materials

Carbon fiber is a revolutionary material that offers numerous advantages over traditional materials such as steel or aluminum. Its unique chemical composition and exceptional physical properties make it a preferred choice for many industries. In this section, we will explore these advantages and show you why carbon fiber is highly regarded.

1. Strength and Lightweight

Carbon fiber is extremely strong and lightweight at the same time. Its layered structure of intertwined fibers gives it a strength comparable to that of steel while being much lighter. This makes it an ideal material for applications requiring high mechanical strength without adding additional weight. For example, in the automotive industry, the use of carbon fiber significantly reduces the weight of vehicles, resulting in better energy efficiency and improved performance.

2. Thermal Conductivity

Carbon fiber also has excellent thermal conductivity. This means it is capable of efficiently dissipating heat, which is crucial in many applications. For example, in the aerospace industry, carbon fiber is used in the manufacturing of aircraft wings, which helps reduce heat buildup and improve flight stability.

3. Corrosion Resistance

One of the most important advantages of carbon fiber is its resistance to corrosion. Unlike steel and aluminum, carbon fiber is not prone to rust or corrosion from exposure to moisture or aggressive chemicals. This makes it an ideal material for applications in corrosive environments, such as the oil and gas industry.

In addition to these major advantages, carbon fiber also offers excellent fatigue resistance, low thermal expansion, and high dimensional stability. It is also transparent to electromagnetic waves, making it an ideal material for applications in electronics and telecommunications.

In conclusion, carbon fiber has many advantages over other materials. Its strength, lightweight, thermal conductivity, and corrosion resistance make it a preferred choice for many industries. Its use improves performance, optimizes energy efficiency, and reduces maintenance costs. It is no wonder that carbon fiber has become an indispensable material in the field of technical innovation and engineering.

The challenges and limitations of carbon fiber

Carbon fiber is undoubtedly a revolutionary material, but like any innovation, it also presents challenges and limitations. In this section, we will explore some of the obstacles we face when using carbon fiber, while keeping in mind the endless possibilities it offers.

High Cost: The Main Challenge

The high cost of carbon fiber is one of the main barriers to its widespread adoption. Producing high-quality carbon fibers requires complex and expensive facilities, as well as a long and meticulous manufacturing process. Therefore, carbon fiber-based composite materials are often more expensive than their steel or aluminum counterparts. However, it is worth noting that carbon fiber production costs are gradually decreasing thanks to technological advances and process optimization.

Despite its high cost, carbon fiber offers significant benefits in terms of lightweight, strength, and durability, making it often a cost-effective choice in the long run in certain industries.

Environmental Impact: Another Challenge to Overcome

The environmental impact of carbon fiber is another concern. The production process of carbon fiber requires the use of chemical precursors and high temperatures, which result in greenhouse gas emissions. Additionally, carbon fiber is non-biodegradable and has an extremely long lifespan, posing waste management challenges.

However, it is important to note that efforts are underway to make carbon fiber production more environmentally friendly. Research is being conducted to find more sustainable precursors and improve manufacturing processes to reduce greenhouse gas emissions. Additionally, carbon fiber recycling technologies are being developed, which will help reduce waste and use more recycled materials in production.

Ultimately, striking a balance between the advantages of carbon fiber and its environmental impacts is crucial. Innovation and continuous research will overcome these challenges and make carbon fiber even more sustainable in the future.

In conclusion, while carbon fiber has challenges and limitations, its potential is immense. The advantages it offers in terms of strength, lightweight, and durability make it an indispensable material in many industries. It is crucial to continue to innovate and develop solutions to make carbon fiber production more affordable and environmentally friendly. With a responsible approach and collaboration between researchers, manufacturers, and users, carbon fiber will continue to revolutionize the world of technology and engineering.

Section 7: Carbon Fiber Innovation at IC-Composite

When it comes to innovation in the field of carbon fiber, IC-Composite stands out with its unique creations and forward-thinking approach. At IC-Composite, we are more than just an online shop for composite materials, we are enthusiasts who constantly push the boundaries of creativity and functionality.

We push the boundaries of aesthetics

Our exclusive carbon fiber weavings are the result of extensive expertise combined with a constant pursuit of perfect aesthetics. We strive to transcend strength and create true works of art in carbon fiber. Each weaving is carefully crafted in our own workshop, reflecting our passion for innovation and art.

Imagine a carbon fiber sculpture that evokes the fluidity of water or the power of wind. Or a woven tapestry that captures the beauty and fragility of nature. At IC-Composite, we don’t just provide materials, we create unique visual experiences that stimulate the imagination.

We open up new functional possibilities

Carbon fiber already offers many unique properties, but we go further by exploring new uses and applications. We collaborate with artisans and innovators from around the world to push the boundaries of functionality.

Imagine a lightweight yet incredibly strong racing car, thanks to the use of our carbon fiber composites. Or lighter and more durable musical instruments that allow musicians to reach new heights. At IC-Composite, we believe that carbon fiber can transform every aspect of our daily lives, offering innovative and sustainable solutions.

And that’s not all. We are also involved in research and development projects that aim to harness the properties of carbon fiber in emerging fields such as medicine and renewable energy. At IC-Composite, we don’t just follow trends, we create them.

So if you’re looking for unique and innovative composite materials, look no further. Visit our online shop IC-Composite and discover our range of exceptional products. Be inspired by the aesthetics and functionality of carbon fiber, and join us in our quest to push the boundaries of innovation.

Visit our shop now and explore a world of possibilities with IC-Composite!